Engineering, Art & Tech

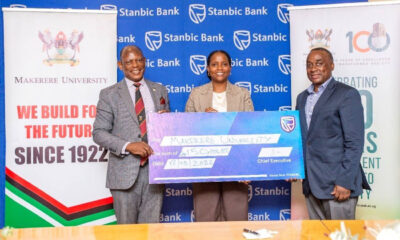

Makerere University Student Laptop Scheme

Engineering, Art & Tech

Uganda Engineering Sector Takes Bold Steps toward Reform and Collaboration

Engineering, Art & Tech

CEDAT and KOICA Partner to Advance E-Learning at Makerere University

Engineering, Art & Tech

Uganda Urged to Strengthen OSHE Enforcement Amid Rising Workplace Injuries

-

Education2 weeks ago

Education2 weeks agoAdmission List to Bachelor of Education External (BED) 2025/26 -Private Sponsorship

-

General1 week ago

General1 week agoRe-advert: Admission to Undergraduate Programmes 2025/2026

-

General2 weeks ago

General2 weeks agoAdmission Lists -Disability and District Quota Schemes 2025/26

-

General2 weeks ago

General2 weeks agoDiploma/Degree Holders Scheme – Self Sponsorship Admission Lists 2025/26

-

General6 days ago

General6 days agoRe-Advert for Applications for Diploma and Certificate Training