Engineering, Art & Tech

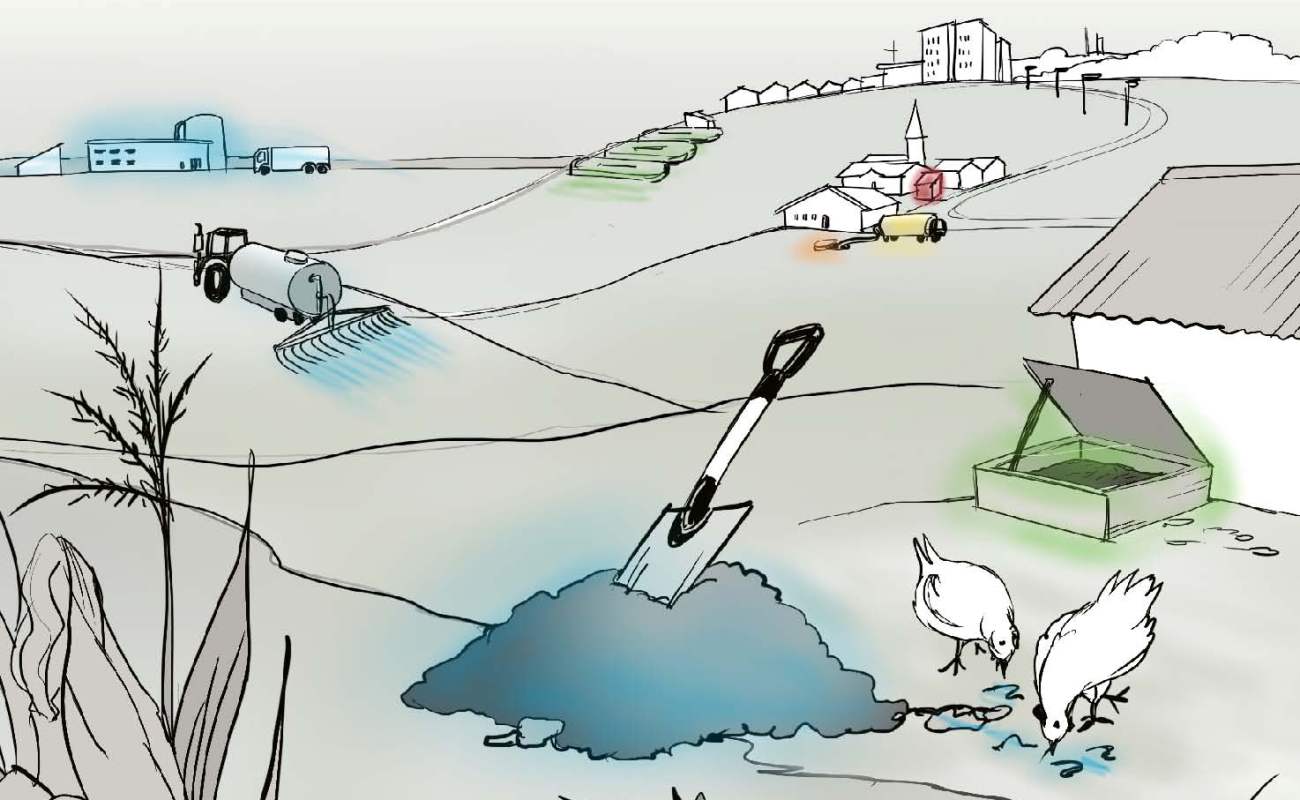

Guide to Sanitation Resource Recovery Products & Technologies

Engineering, Art & Tech

Makerere University Announces Call for Papers for 10th National Conference on Communication (NCC 2026)

Engineering, Art & Tech

Makerere University and University of Warwick Strengthen Ties in High-Level Visit

Engineering, Art & Tech

Makerere and BOKU University Strengthen Ties at Hybrid Renewable Energy Systems Conference

-

General1 day ago

General1 day agoCall for Applications: Diploma Holders under Government Sponsorship 2026/2027

-

General1 day ago

General1 day agoAdvert: Admissions for Diploma/Degree Holders under Private Sponsorship 2026/27

-

Humanities & Social Sciences2 weeks ago

Humanities & Social Sciences2 weeks agoMeet Najjuka Whitney, The Girl Who Missed Law and Found Her Voice

-

General1 week ago

General1 week ago76th Graduation Highlights

-

Agriculture & Environment2 weeks ago

Agriculture & Environment2 weeks agoUganda Martyrs Namugongo Students Turn Organic Waste into Soap in an Innovative School Project on Sustainable Waste Management