Agriculture & Environment

Mak-CAES BioInnovate Project Registers Significant Achievements

Published

3 years agoon

Smallholder farmers in Uganda and Kenya produce a variety of fruits, traditional and exotic vegetables, spices, and herbs that have unique nutritional, nutraceutical and functional properties. However, the value derived from these crops is limited due to postharvest losses, seasonal production, limited value addition and market access problems. Developing and applying affordable food preservation technologies could reduce postharvest losses by up to 68%. Additionally, food preservation by drying not only prolongs shelf life, but it also minimizes storage, transportation and packaging costs.

About the project

In 2017, Makerere University through the Department Agricultural and Biosystems Engineering at the College of Agricultural and Environmental Sciences (CAES) received funding under the BioInnovate Africa Programme Phase II to implement a project titled;“Adaptation and Promotion of Refractance Window Drying Technology (RWDT) for Production of High Quality Bio-products”. The RWDT uses heat to dry fruits and vegetables, while maintaining the nutritive qualities. With RWDT, liquid foods, purees or slices are dried on one side of a thin plastic film, whose other side is in close contact with hot water at temperatures below boiling point. The plastic film, usually in the form of a conveyer, is susceptible to infrared radiation, therefore allowing thermal energy to be transferred from the water to the food. Transmission of infrared radiation stops when the food is dry, and the product scraped off the conveyor. The temperature of the product remains relatively low during drying, resulting in better quality retention due to reduced moisture content and inhibited microbial growth. The heated water is recycled, further improving thermal efficiency of the system.

Project duration and objectives

The three-year project worth 750,000 USD had been scheduled to end in December 2020 but was extended to June 2021 due to the outbreak of COVID19 and the subsequent restrictions aimed at curbing the spread of the pandemic. The development objective of the project was to create new business opportunities in food value addition and agro-processing equipment fabrication. The project specifically aimed to develop a heat drying technology that is affordable yet yields high quality products, even from heat sensitive materials. It also aimed to; support local fabricators to make quality Refractance Window Drying equipment suitable for use by local agro-processors; improve the quality of products, mainly fruits, vegetables and herbs on the Ugandan& Kenyan markets; minimize post-harvest losses; increase the use of locally produced food ingredients derived from fruits, vegetables and herbs; and to enhance collaboration among farmers, agro-processors, researchers and support agencies.

Project activities

Working with various partners namely; Jomo Kenyatta University of Agriculture and Technology, Kenya Industrial Research and Development Institute (KIRDI), TONNET Agro-engineering Company Limited, East Africa Nutraceuticals Ltd (EAN), Food and Nutrition Solutions Ltd (FONUS) and the Ministry of Trade, Industry and Cooperatives, Uganda, Makerere University implemented several activities under the project. These included designing and fabrication of low cost dryers, techo-economic evaluation of the dryers, evaluation of the refractance window dried products, assessment of the capacity of agro-processors and fabricators; training of farmers, agro-processors, and fabricators; and training of graduate students.

Project closure workshop

On 22ndMarch 2022, the research team led by Prof. John Muyonga held the project closure meeting at which they disseminated the findings and outputs. The meeting held in the School of Food Technology, Nutrition and Bio-Engineering Conference Hall was graced by the Vice Chancellor, Prof. Barnabas Nawangwe, the Principal CAES, Dr Gorettie N. Nabanoga, the Programme Manager of Bio-Innovate Africa Programmes, Dr Julius Ecuru, and representatives of partner institutions.

Achievements registered under the project

Disseminating the research findings, Prof. Muyonga noted that the project had registered significant achievements.

Guided by Prof. Muyonga, the project members including; Dr Julia Kigozi (Lecturer – Department of Agricultural and Biosystems Engineering, Makerere University) Dr. Peter Tumutegyereize (Department of Agricultural and Biosystems Engineering, Makerere University), Mr Shaffic Ssenyimba and Mr Raymond Mutumba (both MSc Students at Makerere University), and the TONNET Agro-engineering Company Limited team designed and fabricated several low cost refractance window drying machines. Additionally, the project team optimised the refractance window drying conditions for different products including passion fruit juice, pineapples, mango puree, jackfruit puree and cowpea leaves. They also developed protocols and guidelines for use of refractance window dried fruits as ingredients in foods. Using the RWD technology, the research team has produced a number of marketable products including – dried fruit slices, dices and strips; fruit powders; bread and cake containing refractance window dried fruits; as well as fruit gummies. The team is in the process of evaluating results for refractance window and solar dried pineapple slices. The team is also evaluating results for drinks produced from mixing refractance window dried pineapple powder in water, the different yoghurts, cookies and porridge made with different proportions of refractance window dried jackfruits, and breakfast cereal containing different proportions of refractance dried pineapple.

Other achievements registered under the project included; obtaining a Certificate of Grant of Utility Model from the Uganda Registration Services Bureau patenting the Electric and Biomass Powered Refractance Window Drying Apparatus invented by the research team; training of farmers in the use of Refractance Window Drying Technology and the use of RWD products as ingredients, training of 16 fabricators, training of 6 graduate students (2 PhD & 4 M.Sc.), refurbishment of facilities at Makerere University Agricultural Research Institute Kabanyolo (MUARIK); and publication of 12 articles in internationally recognized journals.

Articles published included;

(1) Adoption of the Refractance Window Drying Technology in the Drying of Fruits and Vegetables in Uganda –Journal of Advances in Food Science & Technology, 1-10;

(2)Design and Evaluation of a Refractance Window Lab-scale Dryer–Journal of Engineering, Design and Technology;

(3) Techno-Economic Analysis of a Refractance Window Dryer Prototype Developed by Kenya Industrial Research and Development Institute -Current Journal of Applied Science and Technology;

(4) Drying Behaviour and Optimization of Drying Conditions of Pineapple Puree and Slices using Refractance Window Drying Technology –Journal of Food Science and Technology, 1-10;

(5) Optimization of Refractance Window Drying Conditions for Passion Fruit Puree;

(6) Optimization of Drying Conditions for Jackfruit Pulp using Refractance Window Drying technology –Food Science & Nutrition;

(7) Performance Analysis of An Arduino Based Calibration and Temperature Control System for a Refractance Window Dryer;

(8) Arduino based control of the Food and Water Conveyance Systems of a Refractance Window Dryer;

(9) Techno Economic Analysis of Refractance Window Drying of Fruits: A Case of Small-Medium Scale Agro Processors in Uganda;

(10) Physicochemical Properties, Sensory Acceptance and Storage Stability of Yogurt Flavoured with Refractance Window Dried Passion Fruit Powder –Asian Food Science Journal, 38-49; and

(11) Exploring the Potential of Jackfruit (Artocarpus heterophyllus Lam), (2021) –Asian Food Science Journal. Page 97-117.

According to Prof. Muyonga, plans are underway to develop a Memorandum of Understanding between Makerere University and a private firm to oversee the utilisation of Refractance Window Drying equipment at MUARIK for commercial production of value added foods. “There are also plans to facilitate three agro-machinery companies – 2 in Uganda and 1 in Kenyato produce Refractance Window Dryers under the guidance of Makerere University and Kenya Industrial Research and Development Institute (KIRDI). We also hope to engage development agencies to support farmer groups to procure Refractance Window Dryers,” he noted while explaining the research team’s commercialization arrangements.

Explaining the design process of the Refractance Window Dryer, Dr Julia Kigozi said the technology is mechanically simple, cheaper to purchase, energy efficient with high drying speed and low operational costs, and ensures retention of product quality. Dr Kigozi revealed that steps were being taken to promote the use of RWD technologies through Jazi Agro-processing Solutions Limited. Jazi Agro-processing Solutions Limited is a private company that specializes in food processing and doubles as a consultancy in regards to agro-processing solutions with a goal of promoting the agro-processing sector in Uganda. The company carries out training and mentoring on fundamentals necessary for the operation of agro-processing industries.

During the meeting, Mr. Raymond Mutumba shared the outreach and dissemination programmes conducted by Food and Nutrition Solution Ltd (FONUS) with regard to the Refractance Window Drying Technology.Based at the School of Food Technology, Nutrition and Bio-Engineering, Makerere University, FONUS provides consultancy services in the fields of food value addition, community nutrition, food handling and hygiene, post-harvest handling of foodstuffs, facilitation of farmer group learning processes and project evaluations.The main purpose of FONUS’ engagement with the project was to promote uptake of the RWD technologies among end users. This was done through a series of engagements with farmer groups, small and medium agro-processors, and processors that utilise the RWD products and ingredients in foods.

Community engagements undertaken by FONUS included a situational analysis on the potential utilization of the Refractory Window Drier Technology in food value addition, training agro-processors in the use of hybrid RWD, and training of medium and large scale agro-processors in the use of RWDT in the drying of fruits and vegetables. In addition, FONUS conducted trainings on the use of RWDT products and ingredients and flavours in foods, and assessed the marketability of RWDT products.

According to Mr. Mutumba, the community engagements revealed that the RWDT presented a viable solution for preservation of fruits and vegetables in Uganda. The engagements also revealed that the incubatees were more willing to adopt the technology compared to already established processors. It was also discovered that more research needs to be done in RWDT energy efficiency if the RWDT products are to have competitive process on the market. The team called for government support to increase uptake of the technology, noting that individuals and small processor groups may not easily afford it.

Addressing participants, the Vice Chancellor, Prof. Barnabas Nawangwe appreciated SIDA for the enormous support extended towards research and training programmes at Makerere University. “The University has reached the 1,000 mark of staff with PhDs, and almost half of these have been trained under SIDA,” he noted. In addition to other research programmes, SIDA supports the BioInnovate Africa Programme. The Vice Chancellor applauded the Department of Agricultural and Biosystems Engineering at CAES for the commendable initiative aimed at improving the quality and increasing shelf life of agricultural products in Uganda. “The products produced out of this initiative can be major exports for Uganda. We need to move towards commercializing our products. We however need to improve our marketing skills,” he explained while cautioning the research team on the importance of marketing the products. He also advised researchers to make use of the Intellectual Property Management Office at the University to patent their products.

Commenting on the significance of agriculture in the development of the economy, the Vice Chancellor said the CAES has a great role to play in improving the sector. Appreciating the research output at CAES, he called on the College to take lead in the establishment of a central business incubation unit to promote research and innovation at Makerere.

In line with 2020-2030 Strategic Plan that aims to transform Makerere into a research-led University, the Vice Chancellor said it was time to do things differently. “At the moment, Makerere is a research-intensive not research-led University. We have excelled in research publications. We need to move towards churning out companies if we are to make positive impact on our economy. You can remain top on research while churning out companies,” he explained, sharing an example of the University of Istanbul that churns out 300 companies per year worth about three billion USD, and is greatly contributing to the development of the country’s economy. The Vice Chancellor echoed the need for Makerere University to make contribution towards the Parish Development Model. “We will be judged harshly if we do not do anything to liberate our people,” he said.

In her remarks, the Principal of CAES, Dr Gorettie N. Nabanoga appreciated SIDA and BioInnovate Africa for the support extended towards the research project. She applauded the School of Food Technology, Nutrition and Bio-Engineering for always writing successful projects. “Despite the small number of staff at the School, they feature prominently in resource mobilization,” she said. She commended the project implementation team for the significant outputs and strong partnerships. “The project has all that is required to be considered successful and is key to obtaining practical solutions for the agricultural sector,” she explained, noting that CAES is academically productive due to the tireless efforts of staff in different units. Commending the quality of the research outputs, Dr Nabanoga said the project would significantly address the current market needs.

Like the Principal, the Dean, School of Food Technology, Nutrition and Bio-Engineering, Dr Abel Atukwase appreciated BioInnovate Africa for the support extended to the project. He expressed gratitude to the Vice Chancellor for his unwavering supports towards programmes at CAES and the University in general. He congratulated the project team upon the worthwhile initiative.

The Head, Department of Agricultural and Biosystems Engineering, Makerere University, Dr. Ivan Muzira Mukisa, acknowledged the efforts of Prof. Muyonga in promoting research and innovation at the College and University in general. “The success we continue to register is largely due to the commitment of staff. Prof. Muyonga has been a key pillar in research, teaching and mentorship of students,” he said. Highlighting the different research initiatives, including the Food Technology and Business Incubation Centre as well as FONUS, Dr Mukisa said the School had greatly provided opportunities for the processors to improve their skills.

Delivering a presentation on government-academia-private sector partnership in technology development and promotion, the Representative of the Commissioner of Small and Medium Enterprises at the Ministry of Trade, Industry and Cooperatives, Dr Steven Mbogo Kirya thanked the sponsors of the project, as well as the partnering academic institutions for the efforts towards advancing agricultural technologies. He called for continued training of the youth and women in the utilization of new technology to boost the quality of agricultural products in the country.

The Programme Manager, BioInnovate Africa, Dr Julius Ecuru acknowledged the great work done by the research team, saying the project demonstrated that it is possible for academia, industry and government to work together to move ideas to the market. He commended Makerere University for winning 8 out of the 20 projects supported under BioInnovate Africa Programme Phase II. He pledged continued support for scientists in the region.

The workshop was moderated by Dr Gaston Ampe from the School of Food Technology, Nutrition and Bio-Engineering, CAES.

About BioInnovate Africa

BioInnovate Africa is a regional innovation-driven initiative stimulating a bio-economy in eastern Africa. The initiative is supported by the Swedish International Development Cooperation Agency (Sida), and implemented by International Centre of Insect Physiology and Ecology (icipe). The initiative supports multidisciplinary teams of scientists, researchers, and innovators to co-develop and pilot innovative and economically viable bio-based ideas, interventions, and technologies. BioInnovate Africa offers grants for innovative bio-based research ideas and technologies with prospects for business and the market. While funding bio-based innovation projects remains the core activity of BioInnovate Africa, the initiative’s strategy now includes developing a knowledge-based bioeconomy in eastern Africa. This is built on the premise that collaboration at the national and regional level, and between researchers and private sector partners, is the surest way to translate scientific outputs into usable, and commercially scalable products and technologies.Current BioInnovate Africa partner countries are: Burundi, Ethiopia, Kenya, Rwanda, Tanzania and Uganda.

Please see Downloads below for presentations from the BioInnovate Closure Workshop

You may like

-

Simplicity, Service & Scholarship: Hallmarks of Professor Livingstone Luboobi’s Legacy

-

Strengthening Grants Management Through Institutional Collaboration and Capacity Building

-

Mak Moves to Revitalize Food Technology & Business Incubation Centre to Drive Innovation & Entrepreneurship

-

Advert: Postgraduate Admissions 2025/26

-

Mak, HERS-EA Discuss Nurturing More Women Leaders

-

Opening KNOSA Learning Forum at Mak

Agriculture & Environment

Mak Moves to Revitalize Food Technology & Business Incubation Centre to Drive Innovation & Entrepreneurship

Published

5 days agoon

July 14, 2025By

Mak Editor

By Ssembogga Derrick

Makerere University marked a significant milestone on Thursday, 10th July 2025, with the launch of the revitalization programme for the Food Technology and Business Incubation Centre (FTBIC). This initiative is poised to position the FTBIC as a national hub for food innovation, student enterprise development, and agro-industrial transformation.

Hosted under the School of Food Technology, Nutrition and Bioengineering (SFTNB) at the College of the Agricultural and Environmental Sciences (CAES), the revitalization of the FTBIC is intended to bridge the gap between academia and industry. “We aim to achieve this by supporting food-based start-ups, enhancing graduate entrepreneurship, and promoting the commercialization of research,” Dr Julia Kigozi, Dean, SFTNB explained. The project receives critical funding from the Makerere University Research and Innovations Fund (MakRIF), which consistently supports innovation and research-based development at the university.

Unveiling a New Strategic Vision

The event, held under the theme “Revitalizing FTBIC to Unlock Innovation and Entrepreneurship Potential among Makerere University Graduates”, marked the official launch of the Centre’s revitalization programme to key stakeholders. It featured the presentation of FTBIC’s new strategic vision and direction, highlighting the commitment of the institution and its partners to fostering graduate entrepreneurship and innovation in food systems. The event also aimed to raise awareness of the Centre’s crucial role in supporting industry, research, and national development.

Participation of stakeholders

The launch attracted a vibrant and diverse audience of over 50 participants. Among the attendees were student representatives; partners from other incubation centers both within and outside Makerere University, including MIIC, UNIPOD, and DGI; as well as representatives from national innovation stakeholders such as Uganda Industrial Research Institute (UIRI) and StartHub Africa.

Most notably, the event was honored by the presence of the Vice Chancellor of Makerere University Prof. Barnabas Nawangwe. The Vice Chancellor commended the revitalization efforts, acknowledging the Centre’s immense potential to incubate hundreds of food-based start-ups and create employment opportunities for thousands of graduates. “The Centre is now well-positioned to become a flagship platform for innovation, employment creation, and agro-industrial development in Uganda and beyond. Makerere University remains committed to supporting such initiatives that align with national priorities and global development goals.”

The event featured the unveiling of the operational framework for the revitalized Centre, highlighting its commitment to innovation, entrepreneurship, and practical graduate training. Stakeholders in attendance expressed enthusiasm and pledged support for future collaboration, research, and product development initiatives aligned with national development priorities. The event also provided a platform to deepen partnerships with private sector actors and development organizations, reinforcing confidence in the Centre’s potential to serve as a national model for university-led incubation.

Agriculture & Environment

SophiA Project Upgrades Medical Infrastructure at Buvuma Health Centre IV, Trains Technicians for Maintenance Works

Published

1 week agoon

July 9, 2025

Overview of the Sustainable Off-Grid Solutions for Pharmacies and Hospitals in Africa (SophiA) Project

Despite ongoing urbanization across Africa, the majority of the population still resides in rural and remote areas, where infrastructure development remains limited. These regions face significant challenges such as lack of access to healthcare, education, clean water, and reliable electricity, contributing to higher rates of illness and poverty compared to urban centres. According to reports, Sub-Saharan Africa has approximately 120,000 public health facilities (22,000 hospitals and 98,000 health posts), of which around 26% lack any electricity access, and only 28% have reliable power supply.

Access to good healthcare is critical for sustainable development. However, many rural medical centres operate under harsh conditions – using polluted water, lacking cooling for medicines, and facing poor sanitation – largely due to unreliable electricity and water supply. Although half of the population in Sub-Saharan Africa lacks electricity, the region has abundant renewable energy potential that can be effectively harnessed through off-grid solar photovoltaic (PV) systems.

To address the above-mentioned challenges facing the African Continent, Makerere University in partnership with 13 organizations across Europe and Africa developed a project titled, “Sustainable Off-grid solutions for Pharmacies and Hospitals in Africa (SophiA)”. The five-year project that began on 1st October 2021 is funded by the European Union (Project: 101036836 – SophiA – H2020-LC-GD-2-3-2020). At Makerere University, the project is coordinated by Dr. Nicholas Kiggundu, Associate Professor in the Department of Agricultural and Biosystems Engineering, College of Agricultural and Environmental Sciences (CAES).

Piloted in Burkina Faso, Cameroon, Malawi, and Uganda, SophiA aims to provide sustainable off-grid energy solutions to rural and remote health facilities, fostering economic growth and ensuring equitable access to energy and healthcare. Using various technologies, such as photovoltaics, solar thermal, electrical and thermal storage, water treatment and natural refrigerants with low global warming potential, SophiA has developed and manufactured locally innovative, modular, affordable and efficient solar powered systems for providing:

- Safe and clean drinking water, free of bacteria and viruses, and deionised water for medical purposes;

- Hot water and steam production for thermal requirements of the hospitals;

- Cooling of medicines and food at +5°C;

- Low temperature storage of blood plasma and vaccines at -30°C;

- Ultra-low temperature storage of sensitive medication (e.g. some Covid-19 or Ebola vaccines) at -70°C.

In addition, PV MedPort, a simple and 100% solar-powered solution has been developed and tested as a mobile health care station in small remote areas in 4 different geographical conditions in Africa. The SophiA system has been manufactured in Africa and will provide, for the first-time, innovative solutions based on climate-friendly natural refrigerants to cover cooling demand for three different temperature ranges (-70°C, -30°C and +5°C). The system has been tested and demonstrated at four rural hospitals in remote regions throughout the African continent covering the major geographical regions and different climatic conditions in Burkina Faso, Cameroon, Malawi and Uganda.

SophiA Project initiatives in Uganda

In Uganda, all Health Centre IV hospitals with surgical theatres have been connected to the national grid except Buvuma Health Centre IV, which serves over 120,000 people scattered across 52 islands. Recognizing this gap, the Ministry of Health selected Buvuma Health Centre IV for the SophiA project to demonstrate sustainable off-grid solutions.

The SophiA System at Buvuma Health Centre IV provides the following services:

- Off-grid electricity supply

- Safe, clean drinking water for patients, staff, and the community

- Hot water and steam systems crucial for maternal care

- Solar-powered cooking and meal preparation

- Cooling systems for surgery and intensive care units

- Refrigeration for medicines at +5°C, blood plasma storage at -30°C, and ultra-low temperature storage (-70°C) for sensitive vaccines such as those for COVID-19 and Ebola

Training of Trainers Workshop

As the SophiA project approaches completion in September 2025, it is vital to establish a skilled pool of technicians capable of handling maintenance and minor repairs of the system components, including solar panels, water treatment units, generators, batteries, and cooking kits.

From June 23 to 27, 2025, Makerere University hosted a comprehensive Training of Trainers workshop. The training programme encompassed a diverse range of topics delivered by subject matter experts from institutions, including Makerere University (Department of Agricultural and Biosystems Engineering – CAES, and the College of Engineering, Design, Art and Technology – CEDAT), Hochschule University of Applied Sciences, and Busitema University. Participants were carefully selected from diverse professional backgrounds, including recent engineering graduates from CAES and CEDAT, Makerere University, University technical staff, personnel from Kyambogo University, officials from Buvuma District Works and Health Departments, and electricians from Kampala City. The training sessions were conducted at Makerere University and Buvuma Health Centre IV Hospital.

Training Modules Included:

- Sustainable energy systems and their practical applications

- Energy generation and storage technologies

- Solar water heating: design, operation, maintenance, and performance optimization of solar water heaters, crop dryers, and concentrating solar heaters

- Solar PV technologies in Uganda: cell technology, system design, operations, maintenance, and hands-on practicals for standalone and grid-connected systems

- Public health implications of water quality

- Water treatment and quality management, including protocols, parameters, and case study on the MCDI treatment system

- Water quality testing methodologies

- Introduction to sustainable refrigeration and cooling technologies

- Environmental impact and safety considerations for refrigerants

- Refrigeration cycles and component overview

- Life cycle assessment of SophiA technologies

- Thermal energy storage within the SophiA system

- Steam as a productive energy source

The Training Sessions

Day One: Introduction to foundational concepts in solar energy technologies

The first day of the SophiA Train the Trainers Workshop focused on building foundational knowledge in sustainable and solar energy systems. Led by Dr. Peter Tumutegyereize and Dr. Francis Mujjuni, participants explored a range of technologies and applications critical to clean energy deployment.

Key topics included:

Sustainable Energy Systems: Introduction to renewable energy systems including bioenergy, hydro, wind, geothermal, hydrogen fuel cells, and battery storage.

Solar Radiation & Geometry: Understanding solar constants, irradiance, and the impact of atmospheric conditions on solar performance.

Solar Thermal Technologies: Detailed look at solar water heating systems (FPCs and ETCs), maintenance, sizing, and solar dryers for agricultural and industrial use.

Photovoltaic (PV) Systems: Working principles, types of PV cells, performance factors, and diagnostics. Practical testing techniques and metrics like Voc, Isc, MPP, and PR were discussed.

Simulation & Application: Olivia Nakiwanuka demonstrated a PVsyst-based simulation of a 2.55 kWp standalone system for a conference hall, showing a high solar fraction (97.88%) and low LCOE (USD 0.03/kWh).

The sessions emphasized practical skills, performance analysis, and real-world application, equipping participants to train others and support solar adoption, especially in rural and off-grid settings.

Day Two: Water Treatment Technologies

The second day focused on water treatment technologies relevant to low-resource healthcare settings. Facilitated by Sneha De and Mr. Duc Dinh Ngoc from Hochschule Karlsruhe University, sessions covered technical, environmental, and operational challenges, with contributions from Dr. Joshua Wanyama on water quality management and Dr. Prossie Nakawuka on practical water testing.

Key challenges addressed included unreliable water supply and contamination in healthcare facilities, emphasizing the need for decentralized water treatment, especially in rural areas.

Sneha De reviewed biological and physical/chemical water treatment methods, highlighting technologies such as activated sludge, filtration, membrane bioreactors, and advanced disinfection techniques. The SophiA modular water treatment system, integrating ultrafiltration and membrane capacitive deionisation (MCDI), was introduced as a scalable solution for producing safe drinking and deionised water for medical use.

Mr. Duc Dinh Ngoc trained participants on the MCDI technology, an energy-efficient method for salt and fluoride removal suitable for low-salinity water.

Dr. Joshua Wanyama discussed the water quality management protocols, outlining key physical, chemical, and biological water parameters and monitoring strategies, including modern IoT-based tools, to ensure water safety and public health.

The day concluded with a hands-on lab session by Dr. Prossie Nakawuka, where participants practiced water quality testing using turbidimeters, incubators, and filtration techniques.

Overall, Day Two combined theoretical insights, technology demonstrations, and practical skills, preparing participants to implement sustainable water treatment and quality management systems in healthcare environments.

Day Three: Refrigeration and Cold Storage

The third day of the SophiA workshop focused on sustainable refrigeration and cold storage technologies tailored for healthcare in Sub-Saharan Africa. Experts discussed energy-efficient, climate-friendly cooling solutions vital for vaccine storage, medicines, and diagnostics, especially in off-grid and rural settings.

Key highlights included the introduction of solar-powered and biomass-based refrigeration systems, thermal energy storage methods, and the use of natural refrigerants like propane, ammonia, and CO₂ as environmentally safer alternatives. Presentations emphasized the critical role of refrigeration in healthcare and the urgent need to replace harmful chemicals with sustainable technologies.

Sessions covered real-world applications such as the SophiA cooling containers in Burkina Faso, safety protocols for flammable refrigerants, and the environmental and economic benefits of solar refrigeration systems assessed through life cycle analysis.

The day ended with an interactive quiz and discussion, reinforcing learning and encouraging participants to apply sustainable cooling practices in their communities.

Day Four: World Refrigeration Day & Field Visit to Buvuma Island

The fourth day of the SophiA Train the Trainers workshop was dedicated to the celebration of the World Refrigeration Day and a field excursion to Buvuma Island, providing participants with a unique opportunity to witness the SophiA system in action. The day was coordinated by Dr. Sarah Bimbona and Dr. Nicholas Kiggundu, who led the delegation to Buvuma Health Centre IV, the pilot site for the SophiA installation in Uganda.

The visit served as both a practical extension of the previous day’s technical sessions and a community engagement event. Participants were able to observe the installed SophiA system, which integrates solar-powered refrigeration, water treatment and steam generation technologies designed for off-grid healthcare settings. During the visit, Dr. Kiggundu provided a detailed briefing to local stakeholders, including representatives from the Buvuma District Local Government, delegates from the Buganda Kingdom, and members of the local community. He explained how the SophiA system will enhance healthcare delivery on the island through reliable cold storage for vaccines and medicines, access to clean drinking water, and steam generated for cooking and use in the maternity wards.

As part of the long-term sustainability plan for the SophiA system, the launch of SophiA Water was announced, an entrepreneurial initiative designed to generate revenue locally for the operation and maintenance of the system.

The field trip ended with a certificate awarding ceremony in appreciation of the participants’ dedication and active engagement throughout the training programme.

Agriculture & Environment

APRC Trains Graduate Students & Stakeholders in the Use of the African Agriculture Adaptation Atlas

Published

2 weeks agoon

July 3, 2025

The Agricultural Policy Research Centre (APRC), housed within the College of Agricultural and Environmental Sciences (CAES) at Makerere University, continues to play a pivotal role in shaping Uganda’s agricultural future through evidence-based policymaking. With a mission to ensure that agricultural policies are grounded in empirical research and data, APRC is actively investing in capacity-building initiatives that empower researchers, policymakers, and development actors.

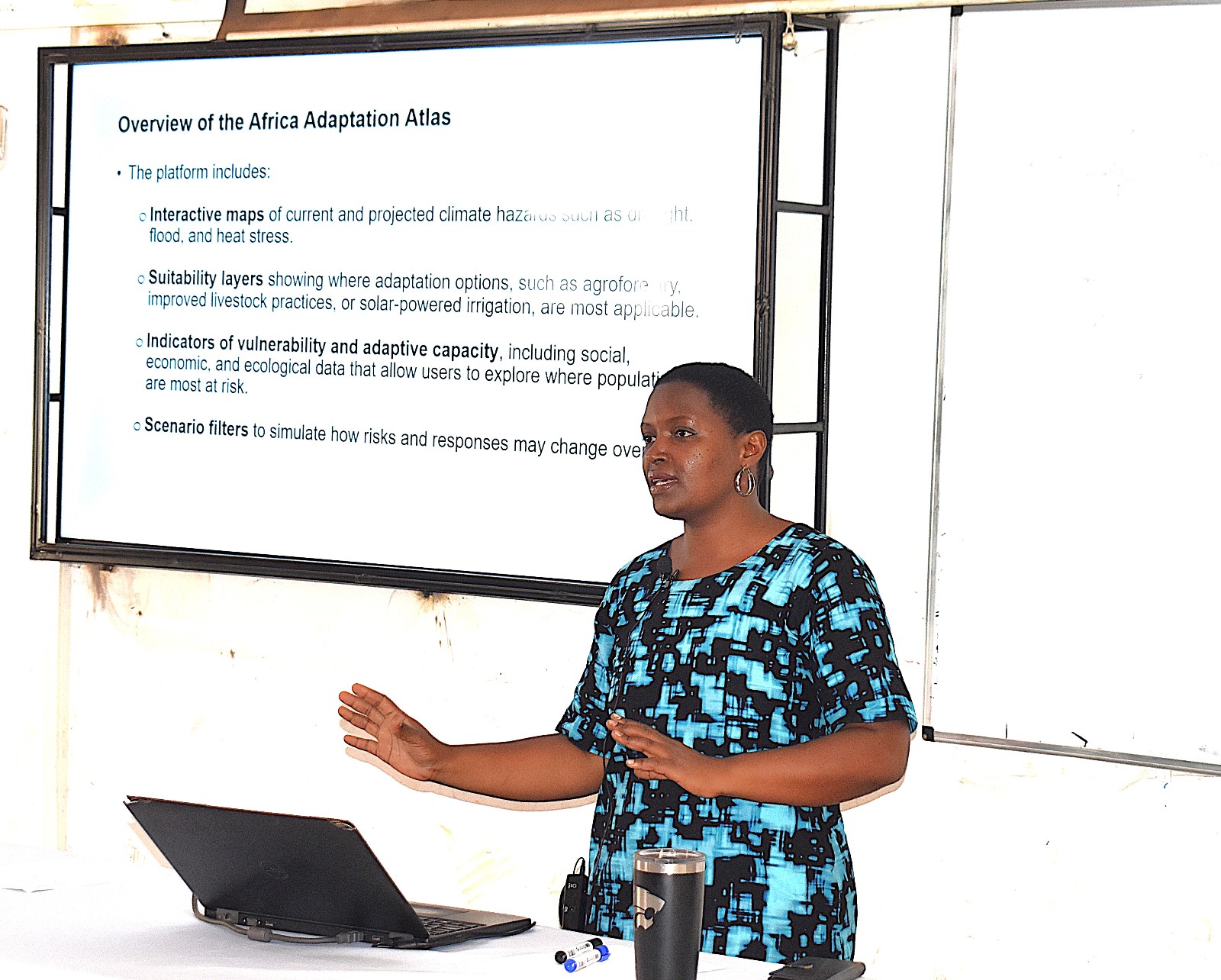

In a significant stride toward building climate resilience in African agriculture, APRC recently organized a two-day intensive training workshop focused on the African Agriculture Adaptation Atlas (AAAA) – a state-of-the-art, web-based decision-support platform that facilitates the integration of climate data into agricultural planning and policy.

The workshop, held on Wednesday 25th and Thursday 26th June 2025 at the School of Agricultural Sciences, Makerere University, targeted two key groups: graduate students on the first day, and university faculty, government officials, and development practitioners on the second. This structure ensured tailored learning experiences for both emerging and seasoned professionals, helping to bridge the gap between academic research and real-world policy implementation.

The African Agriculture Adaptation Atlas (AAAA) is designed to provide dynamic, data-rich visualizations that support informed decision-making in agriculture and food systems across the continent. Through interactive maps and analytical tools, users can explore projected climate impacts, evaluate risks, and identify localized, climate-smart adaptation strategies.

Throughout the sessions, participants received hands-on training in a broad range of AAAA functionalities, including:

- Leveraging the Atlas for research and policy communication: Enhancing the ability of scientists and policy actors to translate complex climate data into actionable insights;

- Assessing projected climate impacts and associated agricultural risks: Essential for forward-looking planning and risk mitigation;

- Identifying climate-smart investment options, with a particular focus on the livestock sector, which is especially vulnerable to climate shocks;

- Analysing gendered vulnerabilities: Examining how climate change disproportionately affects women in agricultural communities;

- Understanding the implications of heat stress on agricultural productivity: Supporting targeted interventions to protect producers and their livelihoods;

- Estimating the economic returns of adaptation strategies: Aiding in prioritizing investments and allocating limited resources effectively.

Prof. Bernard Bashaasha, the APRC Coordinator, emphasized the importance of the training in advancing Africa’s adaptation agenda. “As climate change continues to threaten food security and disrupt livelihoods across the continent, tools like the AAAA, and the skills to use them effectively are essential. They empower decision-makers to craft policies that are adaptive, inclusive, and rooted in science,” he noted.

The workshop was coordinated by Dr. Florence Rwiza, Lecturer in the Department of Agribusiness and Natural Resource Economics at CAES.

More photos from the Training

Trending

-

General2 weeks ago

General2 weeks agoRe-advert: Admission to Undergraduate Programmes 2025/2026

-

General1 week ago

General1 week agoRe-Advert for Applications for Diploma and Certificate Training

-

General5 days ago

General5 days agoMakerere University Fees Waiver for 40 First Year Female Students 2025/2026

-

General2 weeks ago

General2 weeks agoPress Statement on Ranking

-

Health1 week ago

Health1 week agoCall for Applications: Responsible Conduct of Research (RCR) Training Course